Polluter Pays.

This principle basically says - Those who pollute should pay for the cost of the pollution they create.

However is it possible to really determine the cost of an ocean polluted with oil spills or the extinction of an entire species due to chemical pesticide?

This issue of our newsletter looks at one of the ways in which the Polluter Pays principle is being implemented in various countries.

|

|

|

Extended Producer Responsibility

|

|

|

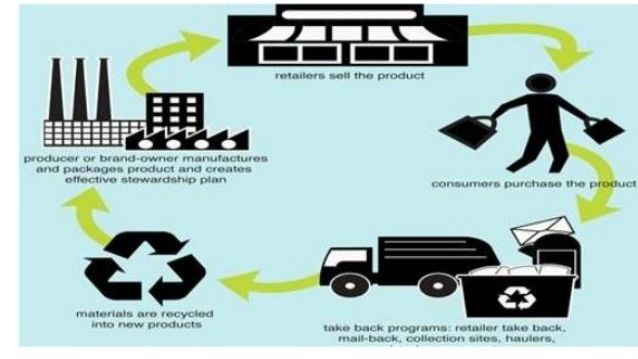

The concept of Extended Producer Responsibility (EPR) is that the responsibility of the producer of a product is extended beyond conventional sales to its post-consumer or end-of-life (EOL) stage. This means that the producer is responsible for collection of the used products or packaging material and ensure its safe recycling or disposal.

|

|

|

The cycle of EPR

Source: slideshare.net.com

|

|

“Extended Producer Responsibility (EPR) is an environmental protection strategy to reach an environmental objective of a decreased total environmental impact of a product, by making the manufacturer of the product responsible for the entire life-cycle of the product and especially for the take-back, recycling and final disposal”, as defined by The Swedish Environment Ministry. EPR extends the responsibility of the producer beyond the point of sale of the product, i.e upto the end-of-life of the product.

Let’s take an example of Tetrapak to understand this better. Tetrapak is a packaging and processing solutions provider. Tetrapak - is a material made by fusing four layers of materials together - two layers of plastic - one of paper and one of metal. While it was an ingenious innovation in food packaging and increased the life span and portability of fresh foods, the material also led to tremendous pollution. The fused materials take a very long time to be broken down by natural bacterias and therefore are effectively non biodegradable.

Tetrapak the company - came under a lot of critcism for the impact caused by their post consumer waste. This led the group to attempt to take the responsibility of their products by working with various stakeholders across the country such as collection agencies and recyclers to collect the waste. They then work to recycle their cartons into various products such as roofing sheets, chipboards, stationery items, desks for schools. Most recently they have redesigned their entire product going in for a completely biodegradable material.

|

|

|

Sources: tetrapak.com and https://www.environmentalleader.com

|

|

|

The idea behind EPR is to encourage producers to consider the end-of-life processing of their products right from the design stage. There by designing products which are long lasting and easily recyclable. There is a significant cost of collection and recycling of these waste which should be borne by the producer and not be passed on to the government or the environment.

Currently in India over 90% of all electronic waste is managed by the informal sector with no safety measures or scientific recycling techniques.

Billions of multi layered plastics (MLP) (primarily mettalised film packets such as those used for chips and biscuits) are either being burnt or dumped into our oceans and landfills causing environmental hazard and serious health repercussions to animals and plants.

To counter this, we have certain EPR policies requiring the producers of such materials to set up systems for collection and recycling.

|

|

(i) Source reduction.

(ii) Waste prevention.

(iii) Design of more environmentally compatible products.

(iv) Closure of material loops to promote sustainable development.

|

|

|

Challenges in implementation

|

|

|

How does EPR work?

EPR demands that if I set up a new industry or design a new product, I must be aware of the entire life cycle of the product - even what will happen to it after it is thrown away.

This means I must understand how the product becomes waste, how this waste is collected and whether there is a possibility to either dispose of it in an eco friendly fashion or whether it can be recycled.

Also it means I must consider the cost of this appropriate disposal and build it into the product.

This is easier said than done.

|

|

Some of the challenges to implementation of EPR include

- Segregation of waste at source will be key for resource recovery of EPR products. Producer companies will need to contribute significantly to improve awareness of source segregation and the need to recycle.

- Plastic waste and E-Waste are well spread across the country. There is a lack of formalized reverse logistics companies as setting up a collection network could be extremely complex and expensive.

- The informal sector manages around 90% of all these waste streams. Upgrading them into the formal means of responsible waste management while ensuring their adherence to compliances will be challenging.

|

|

In 2016, in India, the concept of Extended Producer Responsibility (EPR) was introduced into the Plastic Waste Management Rules, 2016. EPR can be called as cohesion of the following factors:

1. Economic: Shifting the responsibility of the cost of disposal of the products to the producers

2. Environmental: Designing recyclable products and discouraging use of toxic components.

3. Social: Meeting the increased consumer demand for environment friendly products or those manufactured using recycled products.

|

|

|

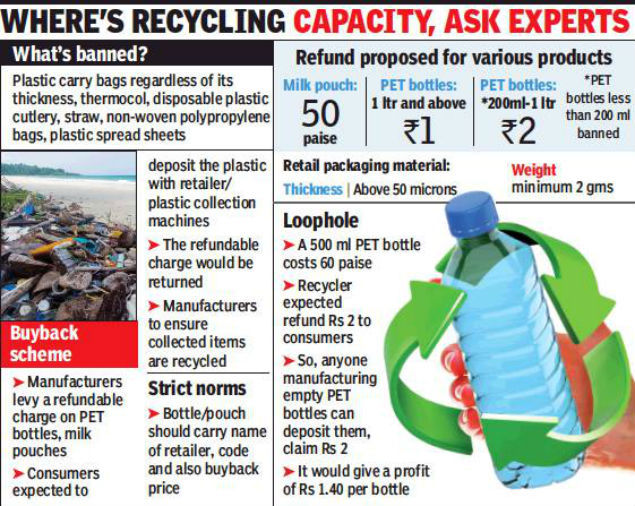

Though India has banned plastic in 18 states, so far Maharashtra is the only state where the Government has introduced a buyback mechanism. In this mechanism, the manufacturer is supposed to print their name, the type of plastic and a recycling price/buyback price in their product. They are then supposed to buy it back from the consumer in that price and then send it to their recycling units.

|

|

|

|

Source: Times of India

|

|

But there is still confusion both amongst the common public; as to who is supposed to collect the products; Is it the shopkeepers who are collecting or the manufacturers. The manufacturers too have their doubts. Some manufacturers feel they don't have the expertise required to set up a buy back mechanism or a recycling unit for that matter. These doubts have not been cleared by the authority for the smooth implementation of EPR. And this makes implementation of the mechanism tougher. Most people in the state don't even have the knowledge that such a policy of buy back exists.

Three months after the ban, there are few manufacturers who have created a buy back mechanism.

|

|

India has currently EPR policies for Electronic waste and Plastic waste.

1. Electronic waste- Under the e-waste management and handling rules, 2011, producers of electronic products were responsible for setting up reverse logistics for collection of E-Waste and channelizing it to State Pollution Control Board authorized recyclers.

2. Plastic waste- The Plastic Waste Management Rules 2016 also enforces EPR for plastic producers in the country and has banned the manufacturing of non-recyclable plastics in two years of implementation.

|

|

|

Organisations working on producer responsibility in India

|

|

|

|

Some industries are taking responsibility of their own products during the entire life cycle of the product. While their efforts are commendable, a more detailed study is required to understand the extent of their success in truly implementing the Polluter Pays principle.

1. Tetra Pak who have been voluntarily collecting and recycling its packaging waste from across the country through channel partners for over 8 years.

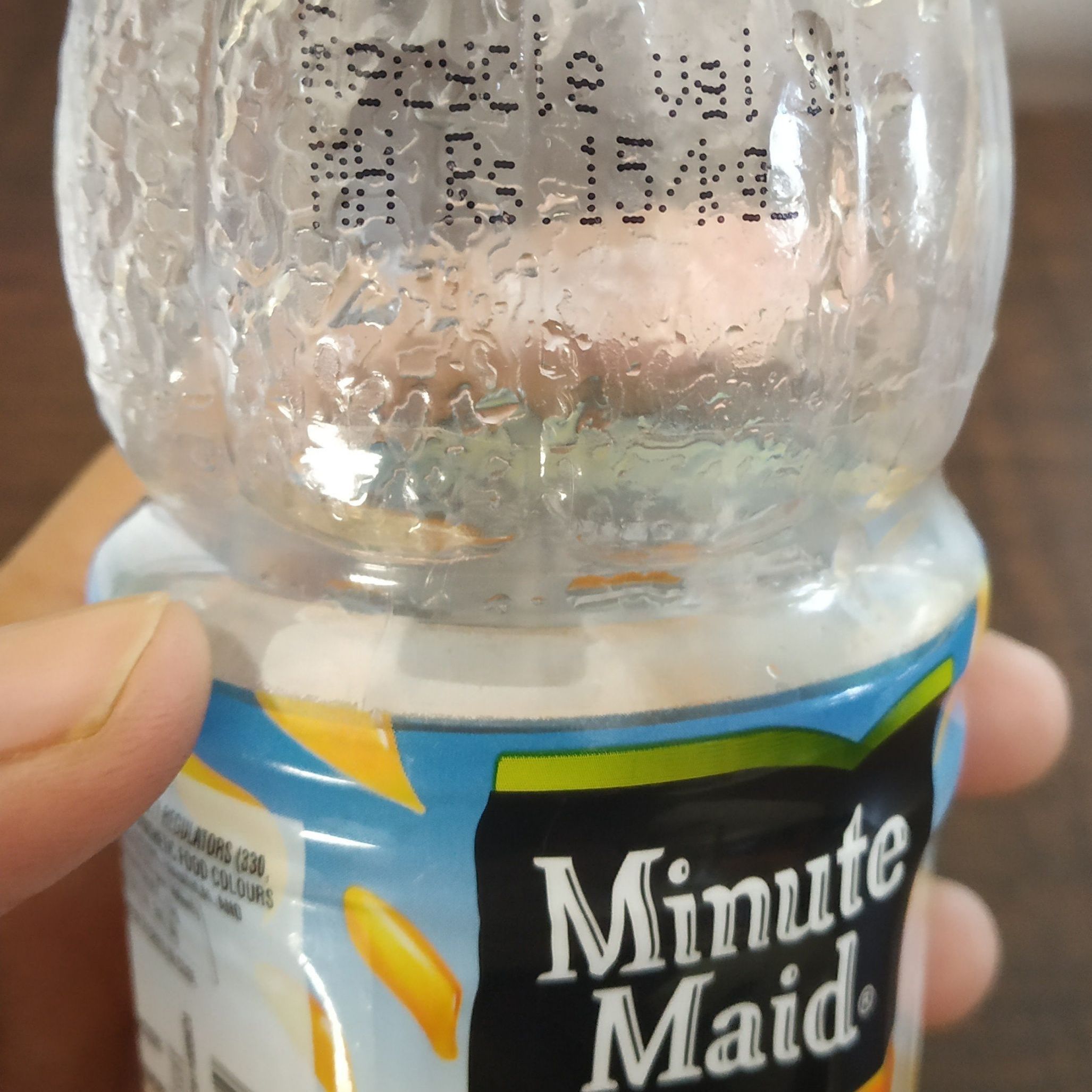

2. Coca Cola, together with Ecoplastics-Continum Recycling has developed a bottle-to-bottle plastic reprocessing plant.

3. Dabur has joined hands with EPR connect, thus helping in the collection and processing of Multi-layer plastic waste and sending for co-processing as refuse derived fuel.

|

|

|

|

A plastic bottle of Minute Maid (Coca Cola Company) with the recycling value imprinted on the bottle.

|

|

|

Image taken at a Marks and Spencer's store where they claim to recycle their packaging waste with a buyback price as shown.

|

|

There are again organisations providing services for producer organisations in recycling their products, called PRO (Producer responsibility Organisations). A Producer Responsibility Organization is a collective entity hired by producers which helps in meeting the collection, recovery and recycling obligations of individual producers.

EPR Connect is one such producer responsibility organisation which provides sustainable end -of- life disposal of plastic packaging waste and e-waste.

|

|

Examples of some of the other organisations in India that facilitate the EPR of other producer organisations are:

1. Terrapro - Terrapro Recycling is a start up launched to address the e waste management in India. It works on the basis of PRO (producer responsibility organisation). They provide end-to-end e-waste management solutions to OEMs, manufacturers and producers of electrical & electronic devices.

|

|

|

2. KaroSambhav- KaroSambhav is another large producer responsibility organisation in the country providing service to many organisations for managing their e waste products throughout the entire life of the product.

|

|

EPR policies should bring about effective collaborations between various

stakeholders like the central and state government, producers, consumers as well as the informal sector to effectively mitigate the impact on climate change andpollution caused by these waste materials. Stringent EPR policies will be instrumental in ensuring implement the sacred 3R principle (Reduce-Reuse- Recycle) hence facilitating a circular economy.

The inclusion of the informal sector would play a key role in the successful

implementation of these policies. For EPR to be successful the waste collectors are a key link in the reverse logistics chain and currently they are the most neglected community.

The onus is now on the producers, to take the required initiatives to address this growing problem. Producers need to contribute significantly and work with specialist collection partners to ensure large volumes of their EOL products are recovered through this reverse logistics network.

The EPR concept is much needed to insist that those earning profits from products that pollute should take ownership of their impact on the environment. However, in the long run, a truly sustainable solution, would be to limit the production of polluting products altogether. While this seems unrealistic in the current scenario, if embraced, it will open up new avenues of design and challenge human ingenuity to invent materials and products that do not pollute the environment at all.

Until such time, EPR is a damage control mechanism. And for now, more stringent enforcement of EPR is the need of the day.

|

|

|

|